Reference Systems

A common starting point is essential, so we begin a project with a reference system (control network) such as a

foundation reference system (FRS), enhanced reference system (ERS), or jig reference system (JRS). This requires

the installation of a series of monuments that are then carefully valued. A control network is typically valued

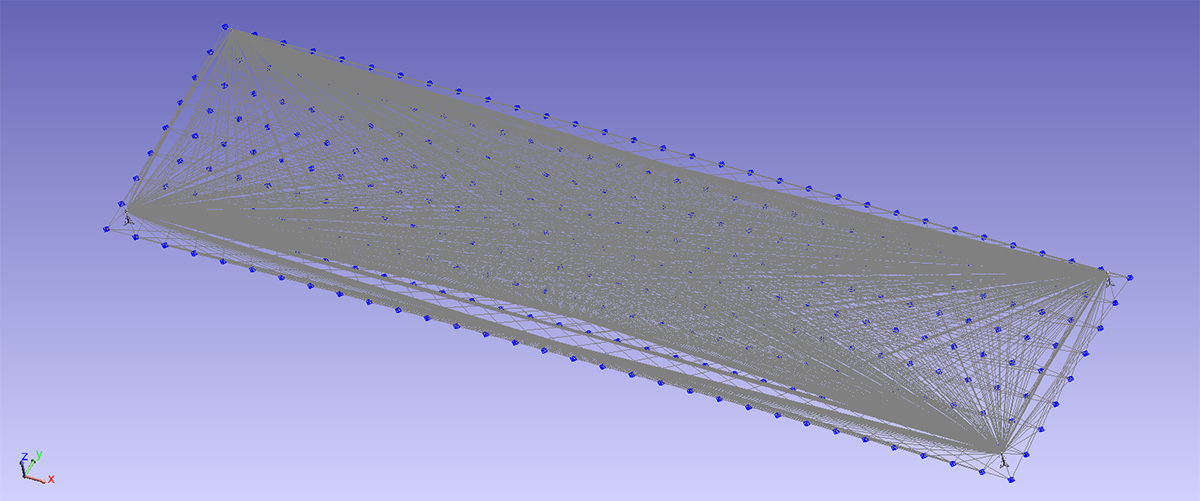

from multiple laser tracker stations with overlapping measurements from different angles. Spatial Analyzer's

Unified Spatial Metrology Network (USMN) function is then used to exploit the extremely accurate distance

measurement capabilities of the laser interferometers found on trackers. USMN uses weighted multilateration

to reduce the uncertainty for the measured monument values. This process yields reference values of extraordinary accuracy.

New control networks are often found on new foundations. Fresh concrete moves (changes shape) significantly during

curing, so periodically we will re-value reference systems on new systems, especially during the first two years.

Tool Setting

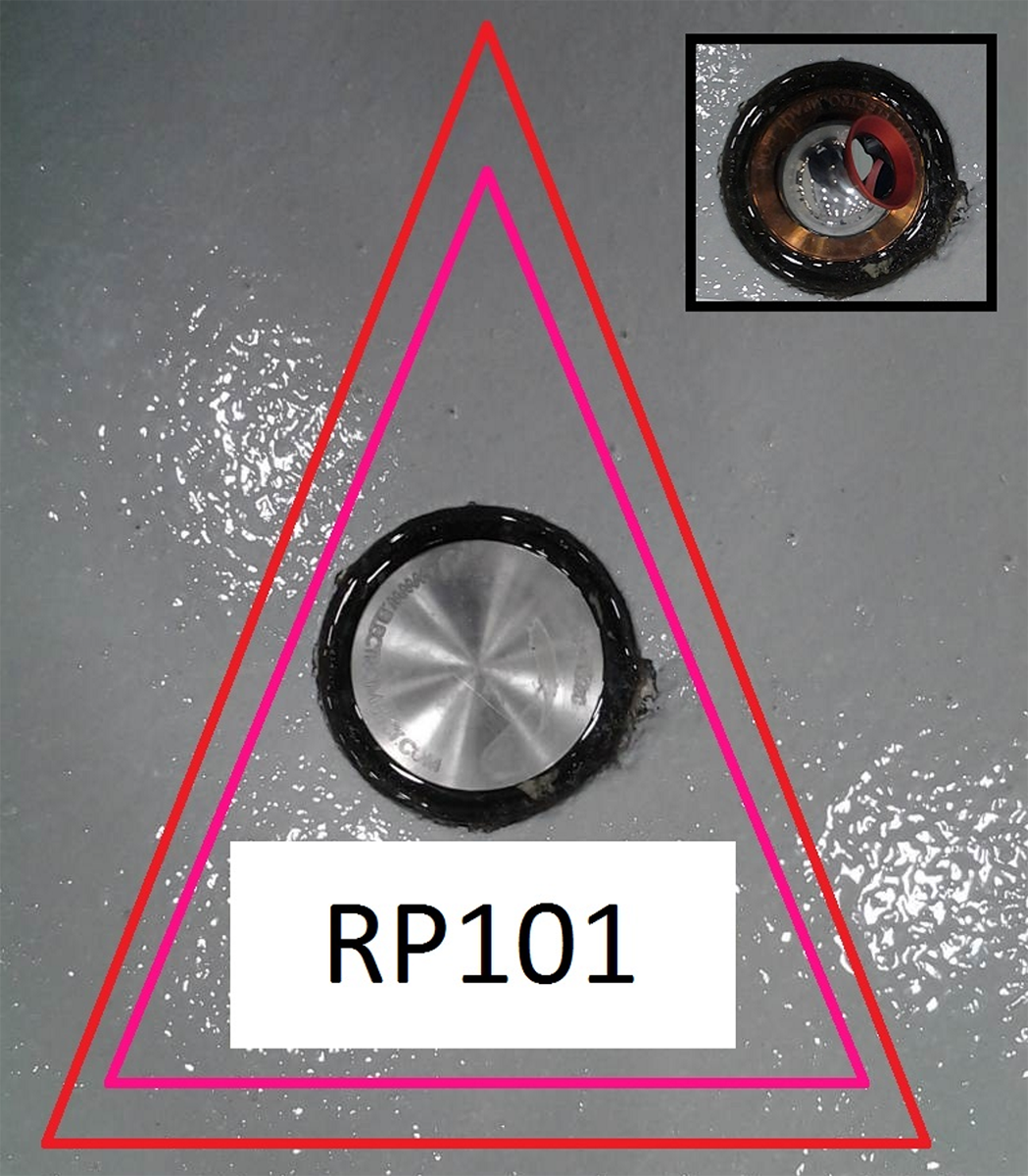

Aircraft tooling has many features, large and small, which require precision "building" or "setting." This work is

typically done using laser trackers and requires multiple measurements: The detail is "set" or adjusted to the correct

location, then checked as a separate operation. Details are usually dowelled to help prevent unwanted movement. After

doweling, a final verification measurement is done.

Determinant assembly is used where practical. For determinant assembly, no allowance is made for adjustment. All parts

are precision made to fit together and meet assembly tolerances. Such elements do not require the setting step and are

just checked, dowelled, and verified.

Part Inspection

Electroimpact's shop includes some very large CNC milling machines, often used for bed assemblies. These require

post-machining part inspection, as do many parts made by our subcontractors. When a bridge-type CMM is impractical,

inspection is performed with laser trackers, or other portable CMMs such as arms, using Spatial Analyzer, Polyworks

or Verisurf.

Scanning

Our Leica ATS600 touchless scanning laser tracker provides very accurate scans over long ranges. It also allows direct

measurement of SMRs just like any other laser tracker. This provides a lot of options for part inspection. We are also

capable of scanning parts using our Hexagon Absolute Arm.

Nadcap AC7130A accreditation

Electroimpact was one of the first companies in the Pacific Northwest to receive Nadcap accreditation for Measurement

and inspection. We have accreditation for:

- AC7130A — Measurement & Inspection (M&I)

- AC7130/1A — M&I — Coordinate Measuring Machines (CMM)

- AC7130/2 — M&I — Laser Tracker

- AC7130/3 — M&I — Articulating Arm

3D CAD modeling and reverse engineering

We have several hundred CAD licenses including those for CATIA V4, V5, Solidworks, Siemens NX and 3DExperience and

experienced tooling, automation and metrology engineers to operate them! Call us to help meet your reverse engineering

and modeling needs.